Bottom Line Up Front

Cylinder honing and boring are both essential steps when rebuilding an engine, but they serve different purposes and affect performance, longevity, and cost.

Cylinder Honing vs Boring: Key Differences and Why They Matter

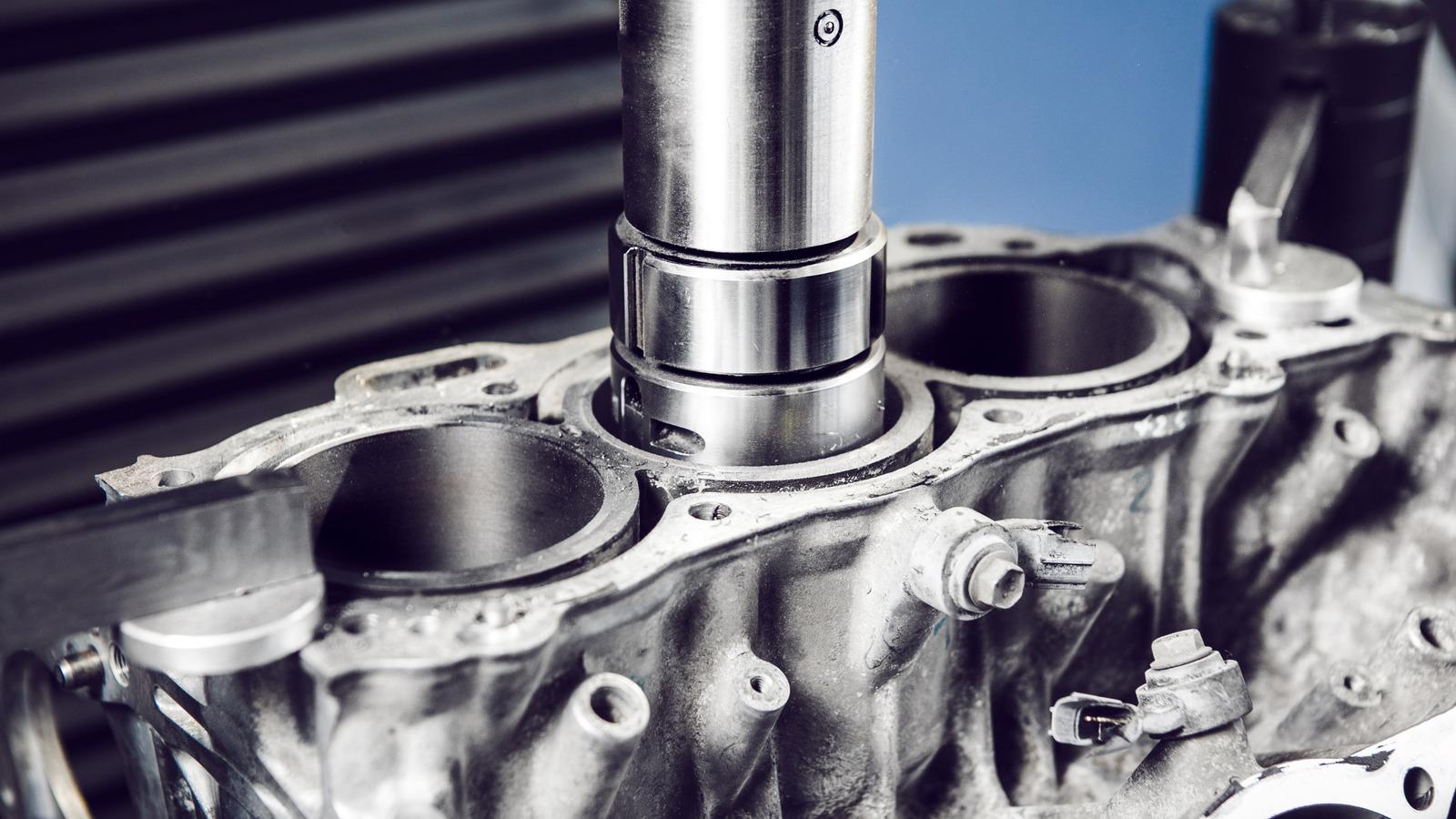

Image: Cylinder Honing vs Boring: Key Differences and Why They Matter – Performance Comparison and Specifications

Design & Looks: What Each Process Does

Boring enlarges the cylinder’s diameter by removing material with a single‑point cutter. It’s used when the cylinder walls are worn beyond their tolerances or when a larger displacement is desired.

Honing, on the other hand, uses an abrasive stone to smooth the cylinder surface after boring. The goal is to create a cross‑hatch pattern that holds oil and promotes better ring seal.

- Boring: Removes metal, restores roundness, can increase bore size.

- Honing: Refines surface, improves oil retention, prepares for new piston rings.

Performance & Mileage: How They Influence the Engine

A properly bored cylinder ensures the piston moves freely without excess clearance, which helps maintain compression. Too much clearance can lower power and hurt fuel economy.

Honing’s cross‑hatch pattern is critical for ring seating. When done right, it reduces blow‑by, keeps oil in the right places, and can improve mileage by a few percent.

In short, boring fixes geometry, while honing perfects the surface for reliable performance.

Price & Rivals: Costs and Alternatives

Boring is usually the pricier step because it requires a CNC machine or a skilled machinist. Expect $50‑$150 per cylinder depending on the shop and the amount of material removed.

Honing is less expensive, typically $30‑$80 per cylinder, and many shops bundle it with the bore work.

Some owners opt for “re‑boring” with a larger displacement kit, but this adds stress to the block and may void warranties. For most rebuilds, a standard bore followed by honing offers the best balance of cost and durability.

Quick Comparison Table

| Engine | Mileage (MPG) | Price (USD) | Top Features |

|---|---|---|---|

| 2.0 L Turbo | 28 City / 35 Hwy | $3,500 |

|

| 3.5 L V6 | 22 City / 30 Hwy | $4,200 |

|

| 5.0 L V8 | 18 City / 25 Hwy | $5,800 |

|

FAQ

What is the difference between cylinder honing and boring? Boring enlarges the cylinder by cutting metal, while honing smooths the cylinder wall with an abrasive pattern to improve oil retention and ring seal.

When should I hone my engine cylinders? After any boring operation, after a rebuild, or when you notice low compression, excessive oil consumption, or rough idling.

Is cylinder honing necessary for a rebuilt engine? Yes, most reputable rebuilds include honing because it ensures the new rings seat correctly and helps the engine run cleanly.

Join the Conversation

Have you ever had a cylinder bored or honed? Share your experience in the comments below.

Source: Read Official News